Our Services

We are capable of providing comprehensive technical support and specification advice to ensure the right supply of electrical low-voltage, medium-voltage, and high-voltage (LV, MV, and HV) cabling solutions are selected to match customer requirements.

Team Force is one of the best service providers you can get to hit performance and specification criteria for planned maintenance, project installations, and fault repair work.

Cable

With more than thirty years of industrial experience, we are confident in our reputation as one of the most prominent professionals in this sector.

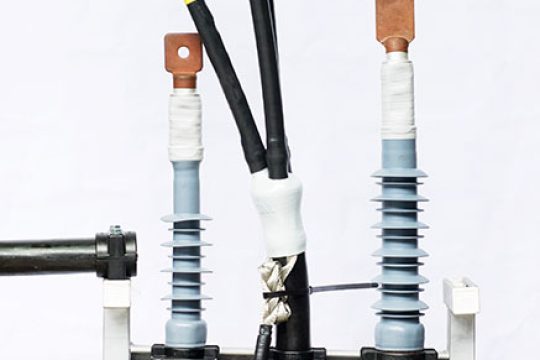

The installation of cables is handled by our incredible in-house team of skilled professionals. The supply and installation of cables and cable accessories such as terminations, joints, outdoor sealing ends, and GIS terminations as well as link boxes and enclosures of various types are among Team Force’s primary areas of operation.

Completing cable jointing as well as termination joints up to and exceeding performance standards ensure the uninterrupted distribution of power supply to vital circuits.

When specifying LV cable joints, one must give careful consideration to the specifications of the cable that is to be joined, as well as the installation application and environmental variables, in order to reduce the possibility of failure in the future.

When specifying LV cable joints, one must give careful consideration to the specifications of the cable that is to be joined, as well as the installation application and environmental variables, in order to reduce the possibility of failure in the future.

Work on fixing electrical cables may involve a high degree of danger when they include live cables. This technique for spiking cables is necessary for determining whether the cable in question is a live cable or a dead cable.

Cable repair is most commonly required as a result of damage caused by excavation works. Mechanical damage can frequently be caused to the cable by either exceeding the maximum bend radius or having the cable “snag and drag” on the bottom of trenches, causing sheath damage through contact with stones or aggregate. However, before the repair process can begin, it is our job to perform a diagnosis and locate the precise location of the damaged part.

It is required to perform cable testing, on cables before they are installed inside the ducting that has been provided, on cable ladders, or buried into the earth.

Upon completion of cable jointing or termination works, cable testing is compulsory as part of cable system commissioning.

It is required to perform cable testing, on cables before they are installed inside the ducting that has been provided, on cable ladders, or buried into the earth.

Upon completion of cable jointing or termination works, cable testing is compulsory as part of cable system commissioning.

We provide the service of cable vacuum to help our clients in solving their cable issues which ingress by water. We use exceptionally robust and dependable vacuum pumping units with high pumping speeds to produce a vacuum in the standard range. These units are equipped with specialised condensers and exhaust devices to pump out the large quantities of water vapour that are generated during the process of vacuum drying.

Our team of highly skilled professions is ready to help our customers whenever they are needed, whether it be for scheduled maintenance or unexpected repairs. We can furnish our qualifications from satisfied industrial clients’ industry upon request.

Transformer Oil

The purpose of the process known as “transformer oil filtering” is to remove contaminants from used transformer oil. Its primary purpose is to enhance the quality of transformer oil, which is utilised in the transmission of electrical power. I, By efficiently and quickly remove traces of water, gas, and particulate matter from the insulating oil, we can improve the functionality of insulating components such as transformers, circuit breakers, mutual inductors, cables, and capacitors.

When the Transformer Oil Filtration (TOF) system is operating properly, the oil will pass through the pre-filter before going into the heater to be heated. Using the vacuum separator, the vacuum pump and the roots pump will be differentiated from the hot oil. After that, the roots pump will fall onto the condenser, which will then turn the oil pump in conjunction with the water vapour molecules that are entering the water receiver. Finally, the oil is discharged after going through the primary filter, the secondary filter, and the fine filter in the oil pump.

After the transformer has been operating for some time, the oil will become less reliable due to the introduction of various contaminants through usage, such as mechanical impurities, moisture, and gas.

Filtration is necessary for both freshly manufactured oil and oil that has been used for some time in a transformer. The filtration apparatus is able to clean low-quality transformer oil of a variety of pollutants, including water, gas, suspended particles, and precipitated impurities. It is able to filter and purify low-quality transformer oil and switch oil, thereby improving the quality of the oil and restoring the viscosity, flash point, and service performance of the lubricating oil. This helps to ensure that the transformer system continues to function normally.

When the Transformer Oil Filtration (TOF) system is operating properly, the oil will pass through the pre-filter before going into the heater to be heated. Using the vacuum separator, the vacuum pump and the roots pump will be differentiated from the hot oil. After that, the roots pump will fall onto the condenser, which will then turn the oil pump in conjunction with the water vapour molecules that are entering the water receiver. Finally, the oil is discharged after going through the primary filter, the secondary filter, and the fine filter in the oil pump.

After the transformer has been operating for some time, the oil will become less reliable due to the introduction of various contaminants through usage, such as mechanical impurities, moisture, and gas.

Filtration is necessary for both freshly manufactured oil and oil that has been used for some time in a transformer. The filtration apparatus is able to clean low-quality transformer oil of a variety of pollutants, including water, gas, suspended particles, and precipitated impurities. It is able to filter and purify low-quality transformer oil and switch oil, thereby improving the quality of the oil and restoring the viscosity, flash point, and service performance of the lubricating oil. This helps to ensure that the transformer system continues to function normally.

Transformer oil’s primary functions are to insulate and cool a transformer. It must therefore have high dielectric strength. Therefore, we also provide calibrated test equipment for performing break down voltage test and water content test on transformer oil. Due to difference design of transformer sampling valve, we also provide the service of assisting client to collect oil sample with specified tool & vessel and deliver to certified laboratory for perform other precision test.

Transformer

After a transformer put into service for years, it has potential of having troubles such as oil leaks, parts aging. We will assist our customer by investigation & provide precise solving method to clear the troubles. We will also design and propose the better solution for lower down the risk of clients’ transformer to create troubles to them again.

In order to maintain conformity with required standards and guarantee the system’s safety, the installation of the transformer must be carried out in a manner that is consistent with the specifications outlined in the design drawings.

Maintenance and fixes are performed on a predetermined timetable. Customers may rely on us to assist them in scheduling the needed maintenance that must be performed on an annual basis.

Earth Link Box

Earth Link boxes have a variety of applications across the high voltage cable industry. We offer a climate-controlled setting that is impervious to the elements for the connecting links that are utilised in the earthing or cross-bonding of the metallic sheaths of high voltage cables. We offer installation and assembly services for earth link boxes of any kind of voltage and also make certain that the boxes are both secure and dry.

Each earth link box is examined on an individual basis. This ensures that in the event of total immersion due to harsh weather conditions, the link box will maintain its dryness on the inside. We offer both short-term and long-term maintenance solutions for our clients.

We are able to assist clients in planning and designing earth link boxes in accordance with their particular requirements and circumstances. Constructed for extreme environments with the highest attainable level of performance. Our earth link boxes have been designed, constructed and tested.

We are able to provide a selection of multiple voltages for the earth link box manufactured by Team Force. All of our high-voltage cable link boxes are made of stainless steel that have been put through rigorous testing. When it comes to earthing or cross-bonding high voltage cables, our link boxes provide a shield impervious to the elements for connecting links. You can find our selection of Earth Link Boxes in our products section.

SF6 Gas

Our company offers services for the recovery and refilling of SF6 gas for those switchgear gas which unable to achieve safety operating criteria.

Insulation of switchgears, circuit breakers, and other equipment used in the transmission and distribution of electricity is accomplished via the use of SF6 in the electric power industry.

The amount of water vapour that is contained within SF6 gas should be kept to a minimum in order to maintain the efficacy of SF6 gas as an insulator.

Moisture can also contribute to an increase in the creation of undesirable secondary decomposition products, which can ultimately result in arcing and the failure of equipment. In order to make things more convenient for our clients, we offer on-site testing.

We provide testing to identify and evaluate the quality of SF6 gas.

The SF6 gas analyser was designed to have zero emissions; following measurement, the gas may be pumped back into the system in the same manner as before.

The amount of water vapour that is contained within SF6 gas should be kept to a minimum in order to maintain the efficacy of SF6 gas as an insulator.

Moisture can also contribute to an increase in the creation of undesirable secondary decomposition products, which can ultimately result in arcing and the failure of equipment. In order to make things more convenient for our clients, we offer on-site testing.

We provide testing to identify and evaluate the quality of SF6 gas.

The SF6 gas analyser was designed to have zero emissions; following measurement, the gas may be pumped back into the system in the same manner as before.

Switchgear

The term “electrical switchgear” refers to a centralised collection of circuit breakers, fuses, and switches (otherwise known as “circuit protection devices”) that have the purpose of protecting, controlling, and isolating electrical equipment. The components of the circuit protection are installed in metallic structures. Switchgear installation performed by trained professionals can provide optimal life-cycle performance from the very first operation. We provide switchgear installations with a high level of reliability and meticulously adhere to best industrial processes for all our commissions.